A hospital’s building automation system is one of its most powerful tools. Properly leveraged, it can massively increase security and efficiency across the facility, saving millions of dollars while creating an overall healthier environment for employees and patients alike. Without the tools to distill BAS data into actionable insights, however, facilities leaders leave all these potential benefits untapped.

Brian Weldy knows a thing or two about intelligent buildings. As Vice President of FacilitiGroup at HealthTrust (a subsidiary of HCA Healthcare), he oversees 178 hospitals and 1,800 care sites, comprising more than 100 million square feet of assets. With over 30 years of experience in healthcare facility management, he’s developed software strategies from the ground up, unlocking the full potential of modern facilities technology.

In a recent talk at HealthSpaces, he explained how healthcare leaders can use their digital assets to achieve ten times the results they’re getting today.

Transforming Maintenance and Capital Investment

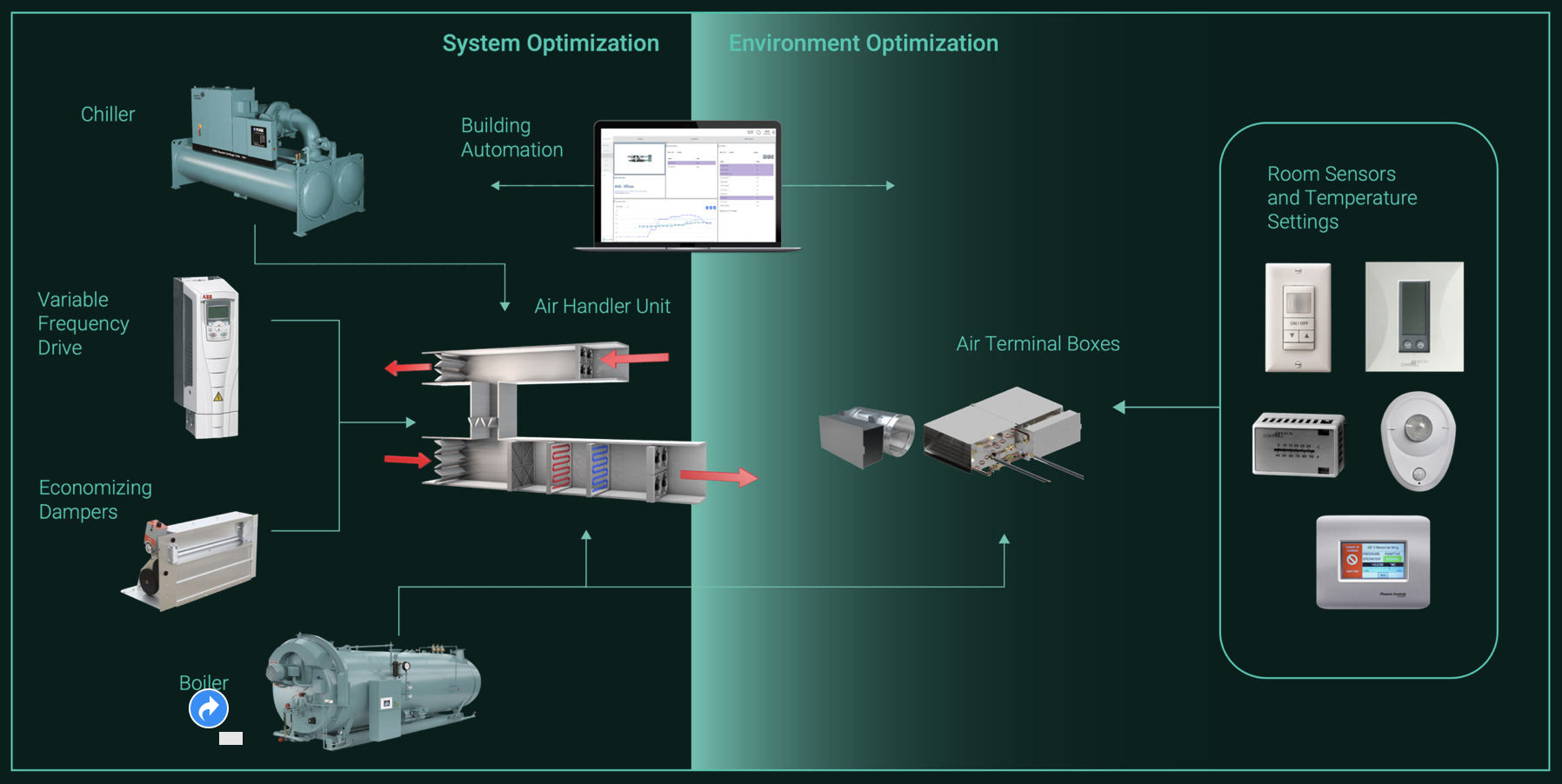

How can healthcare systems extend the service life of their capital assets? How can they reduce energy consumption and improve ESG outcomes? To answer these questions, Weldy zoomed in on one of the most vital components in any healthcare facility: the HVAC system, which accounts for roughly 45% of energy consumption in the average hospital.

"Many facilities are going through the need to replace their air handler units,” he said. “They can cost you anywhere from half a million to a million dollars each. How do you get some service life out of them? How do you spend and invest your money?”

In short: by going virtual. Using historical BAS data and real-time sensory input, digital twin technology can help facilities cut maintenance costs and get the most out of their machines. As Weldy noted, this is hardly a novel approach – he traced its origins to the Apollo program – but it’s one whose potential has only grown as technology advances and facilities age.

"[Digital twin technology] really transforms how to think about maintenance and capital investment."

"The reason digital twins are so powerful is because you use the historical data, and the more data, the better for us to analyze and understand what's going on and what's needed to repair," he said. "It really transforms how to think about maintenance and capital investment.”

Perhaps the most familiar use case is preventative maintenance. With a digital twin, facilities teams can understand and optimize (for instance) a boiler’s operations before problems emerge, rather than reacting when they do.

Then there’s the power to model “what if?” scenarios and plan ahead for a wide range of potential failures throughout the HVAC system. This predictive approach allows facilities teams not only to schedule maintenance more intelligently, but also to get ahead of supply chain delays.

“As we know and watch the supply chain issues going on before us, if we have more heads-up notice about a problem or issue, we can get those parts ordered ahead of time and decrease the issues associated with escalation costs," Weldy said. "It’s a lot more expensive to have a part air-freighted in than to order it through regular scheduled mail.”

From Preventative to Prescriptive

The advantages of a digitally intelligent building go beyond preventative and predictive maintenance. Prescriptive maintenance uses real-time data and historical analysis to make highly precise maintenance recommendations, maximizing uptime and preventing equipment failures.

An intelligent building, properly outfitted with sensors and constantly collecting data, enables a dual predictive-prescriptive approach with the power to identify and address the highest-risk events.

"If you think about the traditional maintenance, you can continue to double down and just be a little more efficient, scale and share resources, train some people, and that's all good, but you're never going to make it to the next level," Weldy said. Only by using an intelligent building approach can healthcare institutions truly get the most out of their maintenance and capital investments.

More advanced systems, naturally, will require more specialized technicians. While these professionals will likely come at higher costs, Weldy argued that they’ll ultimately save institutions money.

"The industry's moving to where we have these very special trained individuals that can go in and service these systems with this technology and be very, very efficient," he said. "While their cost per hour might be higher, their effectiveness is so much improved that their total cost is much, much less.”

Big Data, Big Savings

As healthcare leaders consider where to invest their resources, Weldy encouraged them to make sure they’re getting the most out of their digital assets first. Making a data-informed decision about a corroding air handler coil, for instance, can turn a million-dollar replacement into a $50,000 renovation-in-place. By investing in data collection and digital twin systems, facilities leaders can save both money and energy, while earning their CFO’s buy-in for future investments.

Weldy left the audience with one final word of advice: when he’s faced with a decision about whether to invest in energy efficiency, demand response, or renewable energy, he believes that the fastest option is generally the best option.

“Everything that I reduce will then be at an advantage to whatever I have to add from a renewable standpoint," he said, drawing on his 35 years selling solar thermal systems to conclude that solar isn’t always the best short-term solution. "It's best to lose the weight before you buy the suit, so let us lose the energy first.”

Posted by

Collaborate with your Peers!

HealthSpaces is a community for people that plan, design, build and operate spaces where healthcare is delivered.

June 7-9, 2026 | Braselton, GA

Learn More

-4.png)

-Dec-09-2025-05-48-44-4379-PM.png)

-4.png)

-1.png)

-2.png)

Comments