What are your “Rocks” at the project level?

Budget, Schedule, Safety, Innovation...NOPE! How about formal team alignment, integrated accountability, and timely decisions, with holistic clarity of “WHY” and visual measures of accountability.

I have been teaching variations of this process/structure/mindset to owners, architects, GCs, prefabrication firms, and trade partners. The concepts are the same. The willingness, desire, excitement, and impact have been a joy to see. It’s about creating champions who understand how big of a difference they can make when we teach the WHY and set the table for success!

You might not have “accountability” to everyone at the table, but we do have a “responsibility” to each other.

Lean “the other chapters”

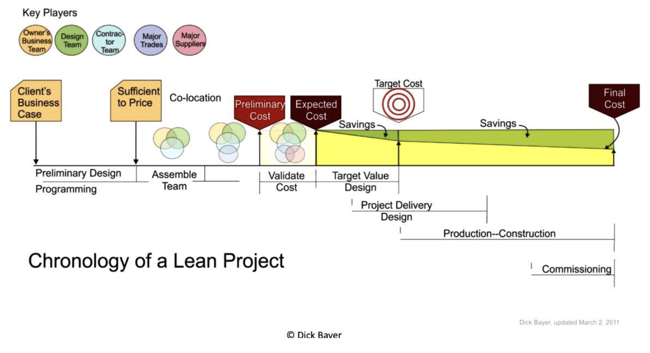

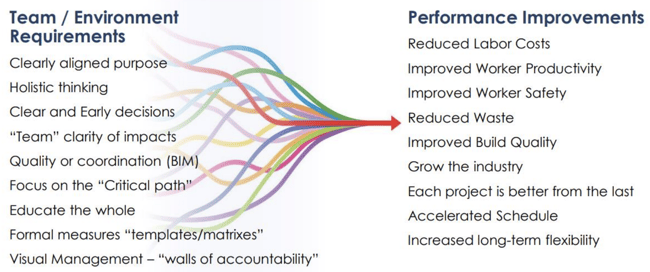

Lean itself gets mixed reviews of value and success. Although the intent or “why” as presented is to reduce waste, the value is so much more.

Should one go take a Lean class, the opportunity to implement is one of simply making the existing environment “norm” just a bit better. The need is for a reconfiguration or realignment of the project delivery flow. Lean by itself can’t do that. However, it is the basis of success.

As presented in a tremendous book, The Lean Builder, the elements of impact at the job site level can and will make a positive impact depending on the individual “champions.” The moment any process that relies on another to be successful is put in a “formal” and “measured” process/structure, you will see improvement.

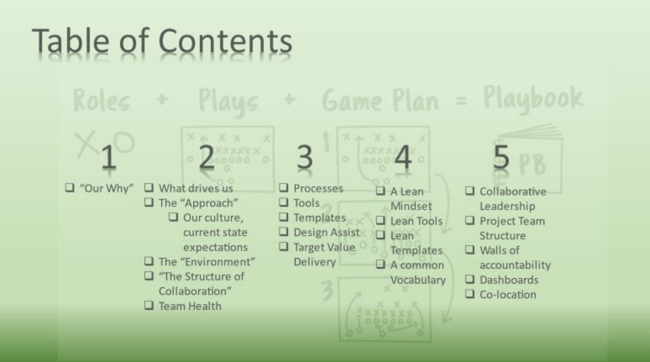

The “other chapters” — the elements that must be added to this equation are those that shift the norm. Those chapters are:

Formal vs. Informal “Everything!” - I have worked with so many talented superintendents and project managers who 100% know what they are doing and will not let a project fail. However, when asked to whiteboard out what that looks like, they struggle. It’s a conundrum that the element that we desire the most, “accountability,” often can’t be achieved because we simply don’t establish the measures to hold folks accountable. Simply having meeting minutes will not achieve the desired result.

The Lean Builder gives you the plan, but we must formalize the process (walls of accountability, formal templates and matrixes, and commitment from day 1 with clarity of expectations). Show me your formal decision-making matrix, communication matrix, conflict resolution matrix, and your Lean templates....and I’ll show you a team way above the norm).

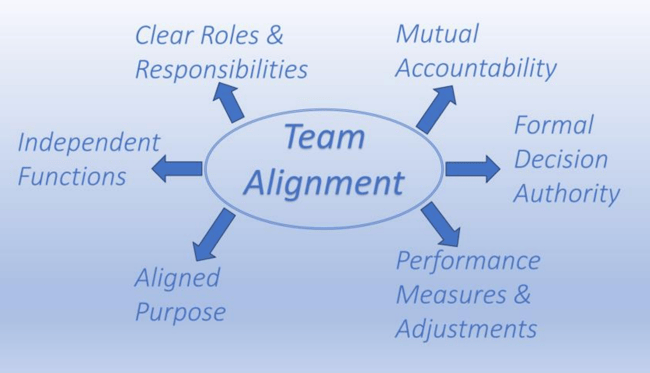

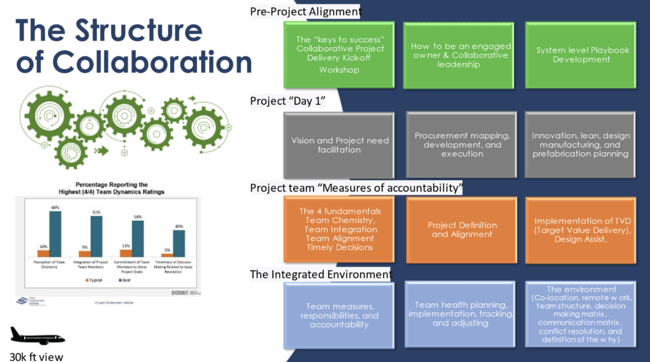

The fundaments of team alignment (clarity of expectations), team integration (the right people at the right time), and extremely important. Timely decisions (with clarity of impacts), if not done formally, absolutely limit the ability to achieve what we MUST have “accountability.”

Team alignment - The simplest moment that we either just don’t understand, value, or champion. If every project team took two hours to gather and run through a defined agenda of what “the team” should know to have the best starting point—this sets the environment.

Topics like the clarity of roles/responsibilities, technical tools, decision-making flow, communication flow, formal templates of accountability, team health, current risk, and risk awareness, etc., make an incredible difference every single time, no matter the project type/size.

Integrated leadership - Understanding the “responsibility” to create an environment of success. You might not be accountable for everyone at the table, but you should have a clear responsibility to each other. If you understand “how and why” that environment is established, matured, and protected, you will have created the greatest impact to the success of each project touched. Plus, your industry respect, level of accountability, profit margin, and predictability will all be positively impacted.

Much of today’s management trends are about “Rocks, Pebbles, and Sand.” We all understand the concept. We also know that just the act of establishing clarity of what goes in each bucket will drive the desire to improve and raise the bar. It also drives us to understand the “why” and not the “how/what.” I find it fascinating to hear what companies define in those three buckets (truly good stuff), but when I ask what the “rocks” are (those major elements that we must focus on first to drive success) at the project level, I get elements that are pebbles or sand.

You want to make a difference at the project level—drive those four elements, “rocks” that we must have in today’s project delivery models (team environment/chemistry, team integration, team alignment, and timely decisions). Show me the formal aspect of how you define each, measure each, and communicate the wins/losses to your team, and I’ll show you a team that will not only be successful but will make each project going forward better instead of just setting the last project as the norm.

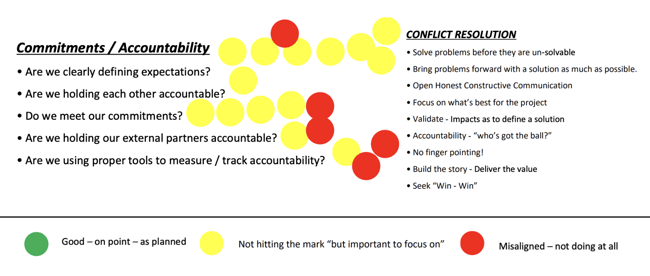

The “Dot test” - I found out a long time ago that what I expected out of an assembly of great talent did not always meet the desired flow/ performance/ synergy/outcome. So, I put together a measure that asked teams how/if their needs were being met. The “normal” process would be to simply “maintain the silos and oil the squeaky wheels.” Simply meaning, when you ask, “how are things?” the typical response is “fine” when it is not. That’s the foundation of only meeting the minimum with the rocks (team environment, team alignment, team integration, and timely decisions). Human behavior says folks will not speak openly due to peer pressure, professional courtesy, and not expecting anything different.

The Dot Test achieves the reality of need without teams having to say a word. It is the culmination of hundreds of project touches. It’s the eight major risk areas and corresponding 10 elements that cause dysfunction in that element. Teams simply are asking to NOT talk—take green/yellow/red dots and put them on the current state against the 8 risks. People will dot the heck out of the walls. It formally gives you clarity of “why” we don’t have the desired outcomes with our primary rocks. Because we don’t formally set them up for success.

How would your team do with just these two examples?

(Remember, it’s about what formal process/structure/tools you have in place to move the specific dots.)

What does it look like...

Formalize these elements “Day 1”: align the entire team, establish clear onboarding, and mine for outliers.

Create a “Playbook”!

Target Value Design

Drive the procurement of knowledge based on the need—no matter the contract type!

Formalize the “expectations” and align with the “Lead,” not the “Lag”.

Denton Wilson, author of this post, will be giving a presentation on Integrated Project Leadership at HealthSpaces '24, taking place June 2-4 in Scottsdale, AZ. Request an invite here.

Posted by

Collaborate with your Peers!

HealthSpaces is a community for people that plan, design, build and operate spaces where healthcare is delivered.

June 7-9, 2026 | Braselton, GA

Learn More

-4.png)

-Dec-09-2025-05-48-44-4379-PM.png)

-4.png)

-1.png)

-2.png)

Comments